Rail Track / Truck Combo Scale

This scale is ideal for bulk cement, aggregate, grain, scrap metal and chemical applications where rail and truck weighing are applicable.

A railroad scale is a weighing device that is used to weigh railroad cars. The scale typically consists of a platform that the railroad car can be rolled onto. The platform is connected to a digital readout that displays the weight of the railroad car. There are different types of railroad scales, but all serve the same basic purpose. Some scales are very simple, while others are quite complex.

We install and service models that qualify for "legal-for-trade" status as well as others. All installations meet the highest standards.

In-pit or above-ground styles, easy-maintenance and high durability models are available. Our scales use stainless load cells for longevity.

This scale is ideal for bulk cement, aggregate, grain, scrap metal and chemical applications where rail and truck weighing are applicable.

The B-TEK Rail Scale can weigh a variety of car sizes efficiently without compromising accuracy.

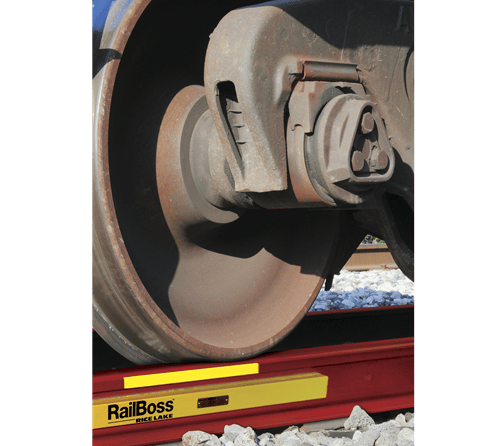

Rice Lake’s non-Legal for Trade RailBoss rail scale is less than one-third the cost of other rail scales and typically takes less than eight hours

The RLP is a tough and reliable rail scale for the weighing of rail cars, with NTEP and Measurement Canada approval for static weighing.

The SURVIVOR PL is a low-profile, pitless modular railroad track scale, excelling in high-accuracy, Legal for Trade weighing applications.

The SURVIVOR RT rail scale is a Legal for Trade rail and truck combination scale, incorporating a rugged, accurate, heavy-duty weighing system with Rice Lake’s

The Weighline rail scale is designed to provide rail car weights quickly, safely and affordably.

A railroad scale is a large, specialized weighing system that is used to weigh railcars and their contents. These scales are typically made up of multiple components, including rails, load cells, and an electronic indicator or data management system.

Railroad scales are used to weigh railcars and their contents as they pass over the scale. The weight is typically displayed on an electronic indicator or printed on a ticket.

The accuracy of a railroad scale is influenced by various factors, with calibration being the most significant. Regular calibration by a trained technician is necessary to ensure accurate weighing. Other factors that affect accuracy include the scale’s usage and the environment it’s placed in. Additionally, different types of railroad scales have varying levels of accuracy, with hydraulic scales being more precise than conventional ones.

Railroad scales are calibrated using weights that are traceable to national or international standards. Calibration is typically performed by trained professionals using specialized equipment.

There are many types of railroad scales including in motion rail scales, hydraulic deck pit scales, and pitless railroad scales. When choosing a railroad scale, consider the weight capacity needed, the level of accuracy required, and any additional features that may be useful, such as in motion weighing or remote monitoring.

When using a railroad scale, it is important to follow all safety protocols and use caution when working around heavy equipment. Proper training and protective gear should be provided to all workers.

Common issues with railroad scales include inaccurate readings, damage to the scale from heavy loads or harsh weather conditions, and malfunctioning equipment. These issues can often be resolved through proper maintenance and repair by trained professionals.

Call (800) 928-5005 or fill out the form below to get started.

Founded in 1985, American Scale provides sales, rentals, service, calibration, and installation of a wide variety of scales for use in numerous industries.

Get 24/7 access to all your equipment certifications. Learn More

© 1985-2024 American Scale Corporation. All Rights Reserved